One World Play Project Case Study

“ALOM is a valued strategic partner! Through their global network we have seamlessly expanded distribution while reducing time and shipping expense. They are incredible!”

Kassie Koontz, One World Play Project

The Challenge

- Inventory control

- West coast based distribution hub

- Growth of international distribution channel

- Delivery to remote locations

The Solution

- North America and Europe-based distribution hubs

- Turnkey packaging and eCommerce fulfillment

- Print production of material collateral

- Fast ramp-up for media-driven order spikes

The Benefits

- Rapid order processing and scalability

- 100% on-time delivery

- Seamless international growth

- Reduced shipping costs

Global eCommerce Scores Winning Goal Through Power of Play

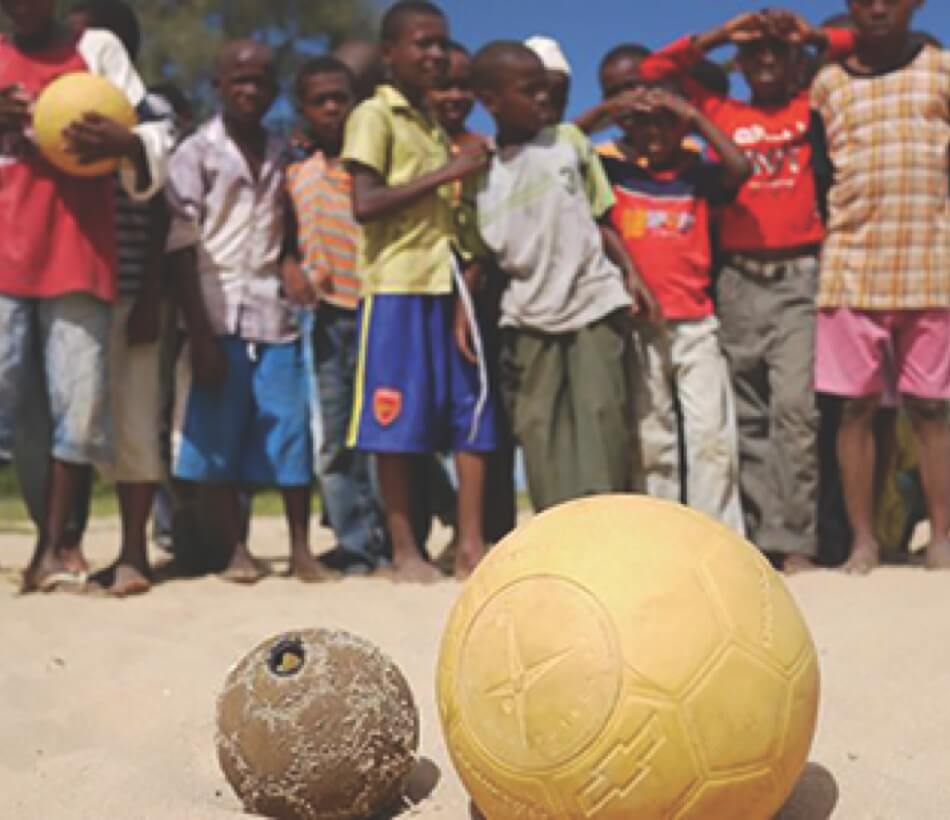

It began in 2006 with a spark of an idea prompted by a documentary showing children in a Darfur refugee camp playing soccer with a ball made of trash wrapped in twine. Four years later in 2010, thanks to generous support from the musician and entertainer Sting, One World Play Project was launched with the mission to have a meaningful impact on youth in disadvantaged communities through the power of play. Since then, with the support of corporate sponsor, Chevrolet, over one million nearly indestructible One World Futbol soccer balls have been distributed to children in over 160 countries.

One World Play Project first learned of ALOM in 2012 when they asked a consultant to not-for-profit organizations to suggest potential fulfillment partners. She recommended ALOM. A conversation followed, then a tour of the ALOM, Fremont, CA facility, and then a series of “roll up the sleeves” meetings. One World Play Project was experiencing growing pains impacting both manufacturing and distribution. They needed much better control over inventory and a west coast eCommerce distribution presence—near the One World Play Project Northern California headquarters—to receive manufacturer shipments via the Port of Oakland, CA.

A key consideration was selecting a partner that could grow with them and provide seamless expansion to global markets. With technologically advanced eCommerce and inventory control systems, a global distribution network, a strong portfolio in print and packaging, and 19 international locations, ALOM was selected as a key strategic supply chain partner by One World Play Project.

The ALOM Solution

ALOM saw the growth potential and loved the idea of supporting kids. So despite initial low volume projections, their supply chain engineers and technology experts worked in conjunction with RHIEM, a Germany-based eCommerce fulfillment partner to develop an inventory management and eCommerce distribution system that could handle forecasted volumes and international expansion.

Controlling shipping costs was a critical requirement. The soccer balls are relatively light but freight costs are based on package volume and the balls do not deflate. With many shipments going long distances, ALOM negotiated volume pricing with major carriers and quickly ramped up a European-based distribution hub.

Paying it Forward

The Buy One Give One business model for the One World Play Project is unique. For every One World Futbol purchased online by a consumer, One World Play Project donates a second ball to youth through not-for-profit organizations working in disadvantaged communities, such as refugee camps, war zones, disaster areas and inner cities. To fulfill not-for-profit back-end order processing, ALOM coordinates with charitable organizations and carriers alike to schedule shipments and determine the best and most cost-effective method to deliver One World Futbols to children in hard-to-reach, remote locations with lagging infrastructures.

Now in its ninth generation of development, over one million One World Futbols have been distributed. Corporate sponsor and media exposure have been so effective that on two occasions order spikes following unexpected media coverage resulted in mounting back-orders. To promptly fill the back-orders, ALOM was in port to meet the next manufacturer shipment and processed all pending back-orders on the same day.