The eCommerce Returns Problem: Focus on Quality First

By Jeremy Murchland

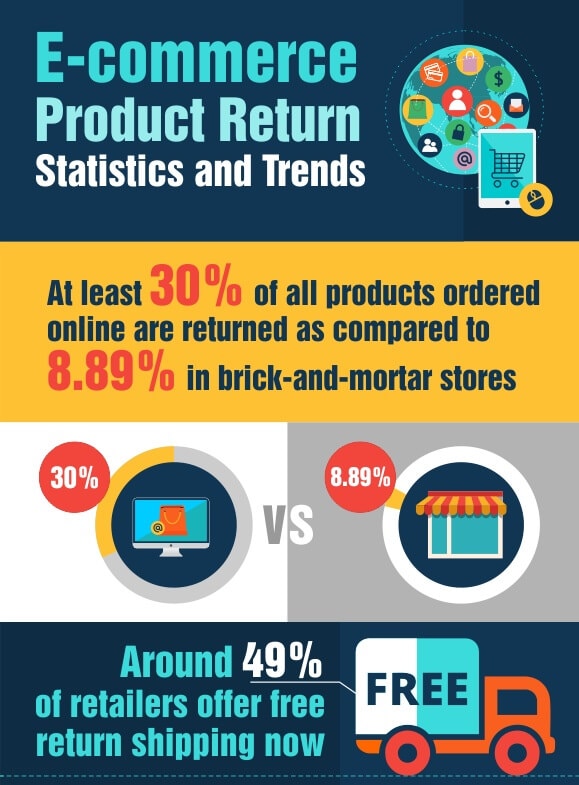

A recent article in Forbes Magazine, “The Ticking Time Bomb of E-commerce Returns” did a great job of summarizing the issue of different cost of returns. It made me wonder what can be done in today’s age of heightened consumer expectations to reverse the trend. To get everyone grounded, I think it’s important to start with some numbers that highlight the extent of the issue:

- At least 30% of products ordered online are returned as opposed to 8.89% ordered in store.

- Around 49% of retailers offer free return shipping further increasing costs

- The top reasons why consumers return products are:

- Damaged product (20%)

- Product received looks different (22%)

- Received wrong item (23%)

- Other reasons (35%)

To compound the issue, many of the returned products are then unable to be resold by the retailer and are either liquidated to a third party reseller for pennies on the dollar or are even destroyed which can have significant long-term environmental implications. The impact of returns on profitability and shareholder value can no longer be ignored, and has to be addressed. What about changing return policies? Some companies are trying to do just this, but are stumbling out of the gate and getting some negative press and customer pushback – just check out this article about Best Buy. Sure, changing return policies is one way to reduce returns, but it can also impact customer satisfaction and overall sales. It is well-known that e-commerce sites with generous return policies have higher sales than those with stricter returns policies. But, maybe that’s a risk many organizations are prepared to take because they see no other option? I suggest that there are other things worth trying first.

Look at the above numbers – 65% of returned product is for reasons completely within the control of the seller. What if you could cut your return rates by a third or more just by addressing these problem areas? Here are some short term tactics I suggest to positively impact your return rate and overall profitability:

- Evaluate your fulfillment processes and packaging materials to reduce in-transit damage: What quality and grade of corrugate are you using for your shipping boxes? Are you using the right amount/type of dunnage to secure and protect your merchandise? Here at ALOM, we invest in the highest quality of shipping materials for our clients because we understand the importance and financial impact of protecting direct to consumer shipments.

- Invest in high quality product photography and descriptions that include customer reviews: Proper lighting, good equipment, high res images, and strong descriptive copy make a difference. Consumers should know what they are buying and what they receive should look just like what’s on the web-site. Customer reviews help by further qualifying sizing, color, and quality information that help a buyer make a more informed purchase decision. If this isn’t happening, there is a marketing and quality issue to be addressed.

- Implement quality process controls with specific focus on inventory management and outbound order processing to eliminate “wrong product shipped” issues: This alone could eliminate 23% of the returns lowering the average return rate from 30% to 23%. What would a 7% reduction in the return rate have on your bottom-line? Quality can’t just be a buzzword in your supply chain – it needs to be the foundation of your business! ALOM performs above a six sigma standard for our clients. We have been ISO certified for over 20 years, and understand the importance of quality, it’s in our blood! Take a closer look at your inbound product inspections, production line quality standards, pick and pack procedures, and order fulfillment systems to ensure processes and checks are in place to make sure your customers get exactly what they ordered. Too many companies sacrifice quality by shortcutting processes, but doing so only has a negative impact on your bottom-line and consumer satisfaction.

- Analyze the returns and close the loop to the photo, description and possibly sourcing of the products. If the consumer does not like the green color, maybe the photo does not accurately reflect the color, or maybe a different green should be offered.

The returns problem is here to stay. With the growth of e-commerce it will be a problem for years to come; however, there are things that can be done to reduce the impact without having a negative result on your brand. Before you consider making a wholesale change to your return policies and upsetting your customer base, look at what’s in your immediate control that can be fixed today. Focus on quality first – quality in your fulfillment processes and packaging materials to reduce returns for damage, quality in your online and print marketing to reduce returns due to consumer perception issues, and quality in your inbound and outbound inventory management processes to eliminate returns due to the wrong product being shipped. COMMIT TO QUALITY!

Contact us today to learn more about how ALOM can help you improve supply chain quality, lower return rates, and enhance your bottom-line financial results.